TURN-Key Systems

Titan Piping Systems Inc. has the experience and capabilities to assist in the designing and product supply. We build, test and deliver a top notch product above expectations for what is required by the customer for the project it is intended for.

Company Mission

Provide highest quality product through our highly skilled, experienced and dedicated employees, state-of-the-art equipment and manufacturing process.

Facility

Our current 15,000 sq. ft. facility offers full service manufacturing, cutting-edge pipe welding techniques, full skid piping assembly with electrical services, and precise machining.

Welding Capabilities

- Over 15 Registered procedures

- GTAW, SMAW, GMAW, and FCAW

- Sch 5 to Sch160 Pipe Wall Thickness

- From ½” Pipe Diameter up to 36”

- All Welders Certified and Registered

- Full Material & Consumables Traceability

TSSA Certified

Titan Piping Systems is certified in accordance with CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Codes:

- ASME B31.1 Power Piping

- ASME B31.3 Process Piping

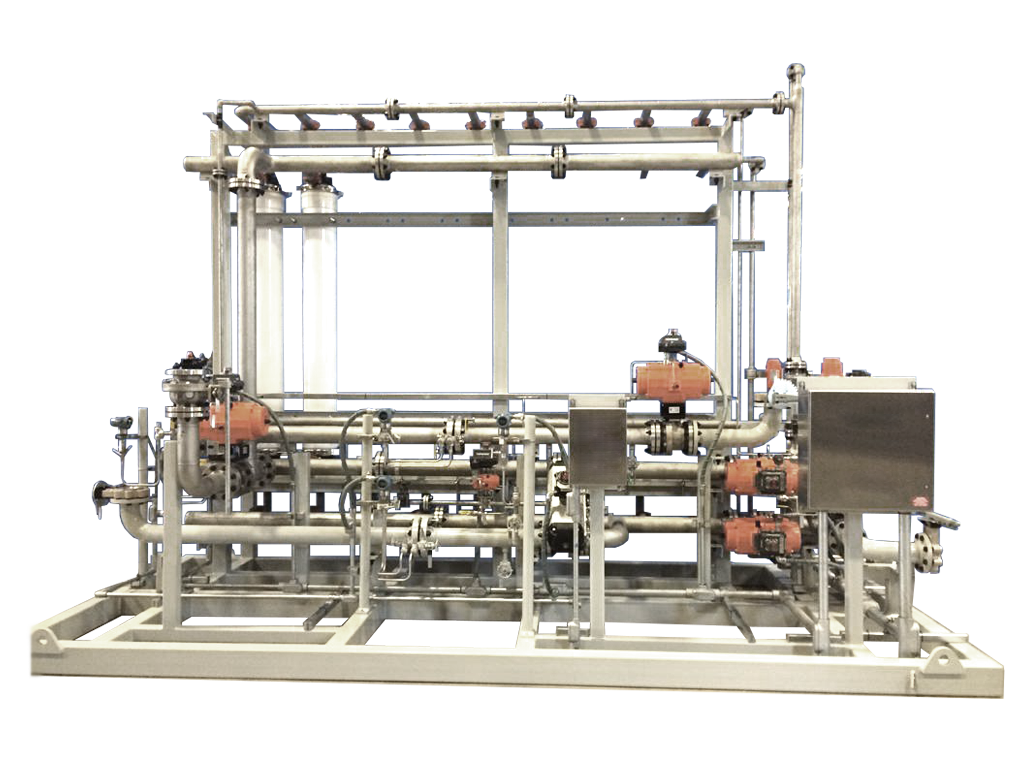

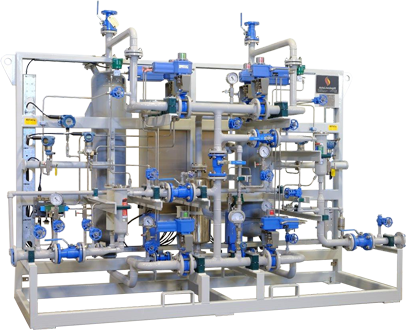

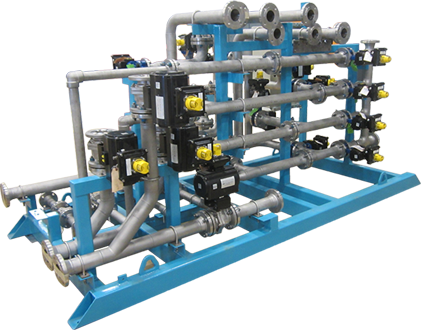

Turn-Key systems

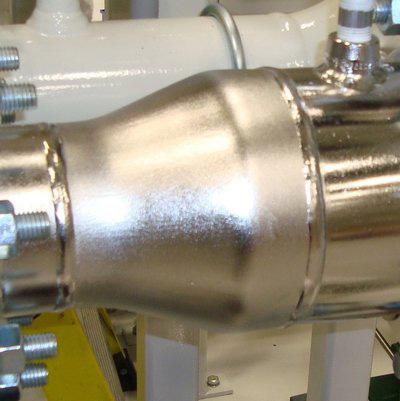

Pipe Spool Fabrication

Electrical Installation

Trident Rainwater Systems

Pre-fabricated Piping Spools

Titan Piping Systems pipe spools are used in various capacities:

- Power and Process Piping

- Ultra-Pure Water Systems

- Ozone Generating Systems

- Vessel Internals

- Large Water treatment Facilities

Skid Fabrication & Assembly

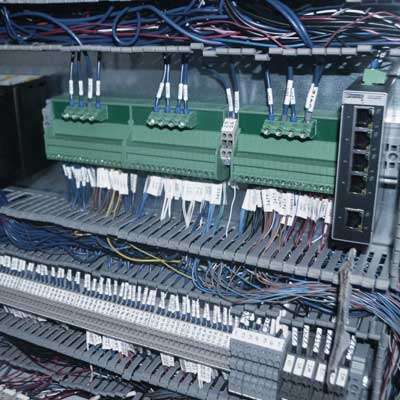

Our staff expertise extends to the following areas:

- Stainless skid fabrication

- Final skid assembly

- Electrical Panels and Installation

- NDE Testing, including Hydrotesting

- Final QA inspection of assembly

- CSA and ESA certification

Surface finish and passivation

Passivation

Glass bead blasting

Electro polish